You're redesigning a piece of machinery or implementing a new manufacturing line, and you need to select a programmable safety control system to monitor all of your safeguarding devices. There are a lot of options out there, so how do you choose?

Here are the top ten things to consider when reviewing your options:

1.Number of I/O - A good place to start is determining the number and types of Input and Output devices that will need to be connected to the controller. With outputs, you need to determine if feedback is required and whether each output is required and whether each output needs to monitored individually (this can increase the number of inputs required).

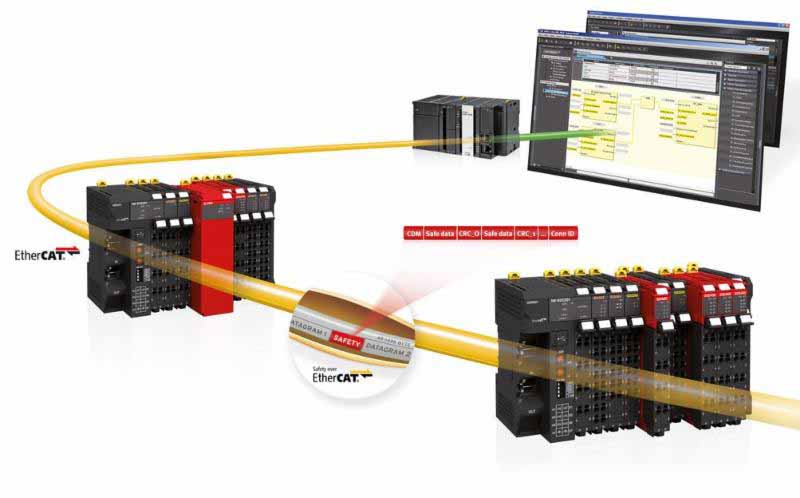

2. Safety I/O connectivity - It is important to consider the type of connection needed. Depending on the controller used and the hazard classification, the numbers of devices that can be connected to an input card or the controller itself can vary. Continue reading