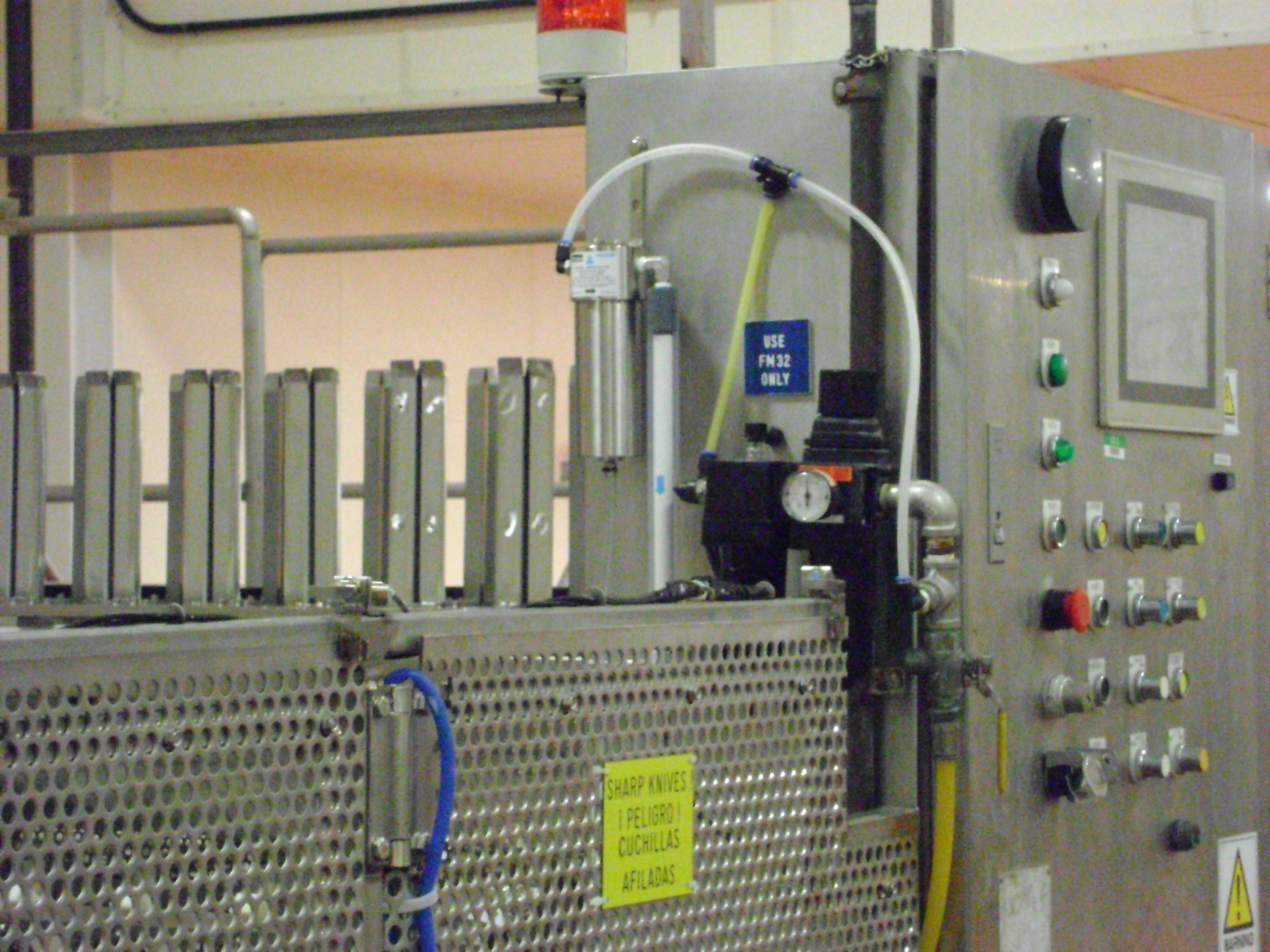

Compressed Air Dryers

A large number of companies need dry air in order to complete their production, maintenance or storage activities successfully. Often needed on an on-going basis, it’s vital to find compressed air dryers that are dependable and require little or no maintenance. We are a leading provider of advanced compressed air solutions, providing an advanced range of air dryers that are specifically designed to give straight-forward, trouble free use.

Contact UsCompressed Air Dryers with Many Benefits

Coalescing Air Filters

Coalescing Air Filters remove dirt, water, and oil in compressed air and other gases to maximize uptime and save money.

- Remove 99.99% oil, water, and solids at .01 micron.

- Extremely long filter cartridge life.

- Low-pressure drop.

- Protect and increase the efficiency of costly equipment.

- Options include differential pressure indicator to alert you when the element needs to be replaced.

- Available in both aluminum and stainless steel.

Membrane Air Dryers

Membrane Air Dryers are small, lightweight, and require no electricity. A reliable, efficient and economical alternative to PSA and refrigerant dryer technologies. Parker Balston IT series membrane dryers are rated for a dewpoint of +35F and the 76 series dryers can reduce the dewpoints to as low -40F.

- Explosion proof.

- Silent operation.

- Very minimal maintenance, with no desiccant to change.

Find Out More About Our Compressed Air Dryers

We are an established provider of automation, engineering and custom painting for a number of different industries. Creative and inventive, we are able to create custom answers for our customers, giving them products which are tailored specifically to the needs of their operation. To find out more about what we can offer, or to discuss your requirements with us, call us at (800) 843-5558.