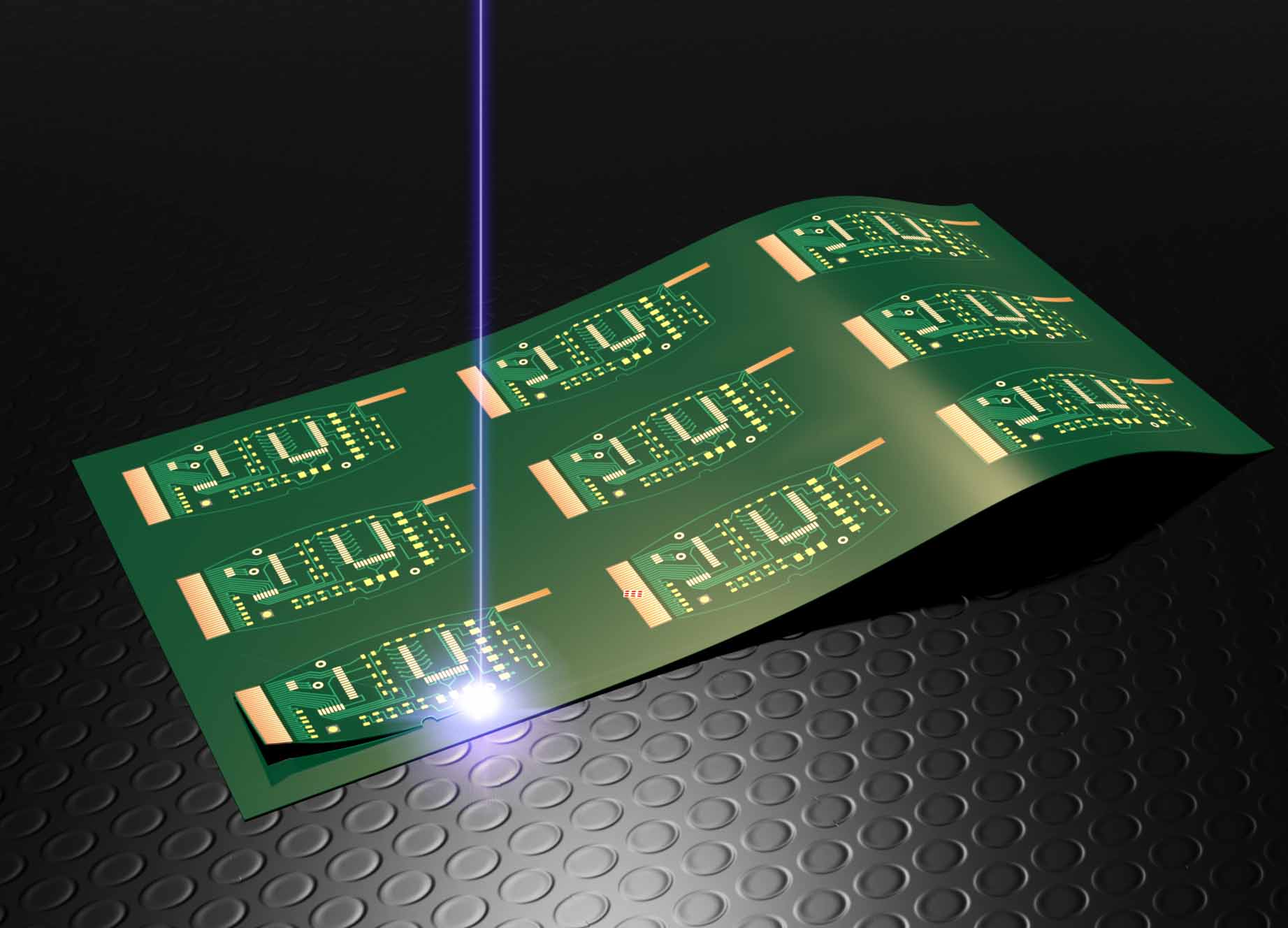

Laser Marking Machines

With industrial and governmental regulations, as well as exceeding growing customer expectations, laser marking has become vital. A laser is arguably the best way to permanently mark parts. Lasers require little to no maintenance compared to all other marking systems and generally require no consumables.

Learn More

Advantages of Laser Marking

Laser marking is a permanent and flexible technology that can be used in a variety of applications such as food, medicine or electronic goods. Whether the application is batch, serialized number, best before date, official logos, or consumer products, laser marking is the perfect solution.

- Ensures there are no extraordinary costs or lawsuits for missing, incorrect, or illegible labels.

- Automatically store vital information to your company’s traceability process.

- Instantly verify readability.

- Laser marking and verifying in the same operation reduces your machinery footprint.

- Adheres to the highest hygienic and aseptic design requirements.

- Never worry about print heads to clean or platter.

- Inkjet printing requires the heads to be cleaned with harsh chemicals. Operators typically wear a respirator as the cleaning chemicals are toxic. Laser marking ensures employee safety.

- There is little to no maintenance which means more time marking and less time maintaining, resulting in a greater ROI.

- Clean marking is now possible for 3D surfaces, such as stepped, sloped, curved, conical and spherical surfaces without any additional software.

- Resistant to counterfeiting and cannot be removed.

- Efficient production in high quantities through automation.

Our laser markers are great for deep or shallow engraving in metals, marking on plastics/resins or plastic films, and for fine processing.

Learn more about laser marking today

We are an established provider of automation, engineering and custom painting for a number of different industries. Creative and inventive, we are able to create custom answers for our customers, giving them products which are tailored specifically to the needs of their operation. To find out more about what we can offer, or to discuss your requirements with us, call us at (800) 843-5558.