Are Industrial Robots Right for You?

by Sky Goller

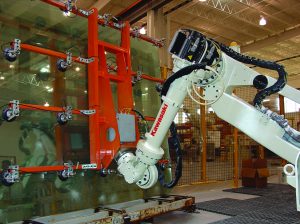

If you’re considering introducing industrial robots into your production line, it is a good idea to examine all the advantages and disadvantages they will bring to your company. Industrial robots increase the efficiency of your production process because; there are endless amounts of tasks and functions they can be programmed to carry out. Robots have a higher accuracy level which allows them to achieve higher quality products while using a fraction of the time and resources that humans in your production line would.

Robots are capable of working more demanding hours than employees without losing efficiency over time. Typically, replacing one person for a robot on the production line increases output by 40% in the same amount of working hours. Robots do not require holiday pay or sick leave, either. With the ability to perform higher levels of accuracy, your company is capable of achieving exceptional levels of quality in a reduced amount of time. In turn, you can increase profitability and lower the production cost per product by reducing the amount of time and resources used.

Additionally, an industrial robot can improve your employee’s working environment. You have the option to assign tasks to robots that are too dangerous or dirty for your employees. Attain peace of mind knowing your robot will not make potentially hazardous mistakes due to fatigue or distractions. Repetitive and strenuous tasks will no longer be a danger to your employees. Industrial robots are especially useful in a manufacturing process that includes repetitive motion whether it is a lower-quality task or high-quality precision.

In today’s constantly evolving market it important to consider a quick ROI option that is flexible and versatile to grow with you. Increase the efficiency of you manufacturing floor by investing in automating with industrial robots. If you have a repetitive, difficult, or dangerous task, consider an industrial robot today.